Computer vision is a branch of artificial intelligence that mimics aspects of the human visual system, allowing computers and systems to interpret and extract valuable insights from visual data. This includes various input forms, such as digital images, videos, and more, enabling machines to understand and analyze visual information effectively. Imagine a computer that can ‘see’ the world like you do—that’s computer vision!

The manufacturing sector is experiencing significant growth, driven by increasing product demand. Innovations in technology and automation are accelerating this expansion, helping companies boost efficiency and increase production. As industries evolve, the need for advanced solutions to optimize operations and elevate quality becomes increasingly essential.

In this blog, we will discuss how computer vision is transforming the manufacturing industry. We’ll explore how it enhances production lines, advances quality control, and streamlines maintenance processes. Additionally, we’ll examine how this technology is set to shape the future of manufacturing, driving greater innovation and efficiency. Discover the impact of computer vision on manufacturing as well as AI solutions for manufacturing and its role in advancing production techniques.

Rising Production Demands: Why Manufacturing Needs AI Now

As global demand for high-quality products surges, the manufacturing sector faces significant pressure to scale efficiently. The increasing need for diverse and reliable products presents both opportunities and challenges for manufacturers, pushing them to innovate continuously to stay competitive.

Challenges of Meeting Demand with Traditional Methods:

Traditional manufacturing methods are struggling to keep pace with this rising demand. High labor costs, production bottlenecks, and inefficiencies in quality control are major challenges. As production volumes grow, maintaining consistent quality and efficiency becomes increasingly difficult. This underscores the need for advanced technologies, like AI, to bridge the gap and meet evolving market demands.

Automation: The Backbone of Modern Manufacturing

Automation is revolutionizing the manufacturing industry by boosting efficiency, lowering costs, and drastically reducing errors. With automated processes, companies can achieve faster and more consistent production, allowing them to meet growing demands without compromising on quality. Streamlined operations lead to higher productivity and reduce reliance on manual labor, enhancing workplace safety while minimizing the risk of human error.

How Computer Vision is Elevating Automation:

Computer vision is pivotal in advancing automation by allowing machines to “see” and process visual data. The global computer vision market in 2020 was valued at $11.32 billion and is projected to grow at a CAGR (Compound Annual Growth Rate) of 7.3% by 2028. The industrial segment alone was responsible for around 51% of the market revenue, with computer vision in manufacturing processes contributing more than half of the total global share.

This technology enables automated systems to perform sophisticated tasks like quality control, defect detection, and precision assembly with remarkable accuracy. By incorporating computer vision, manufacturers can uphold high standards, reduce waste, and maximize efficiency. As automation technology progresses, computer vision becomes a crucial tool, driving the next generation of innovation and performance in the manufacturing world.

Let’s explore some applications of computer vision in the manufacturing industry.

Applications of Computer Vision in Manufacturing Industry

#1 Quality Control

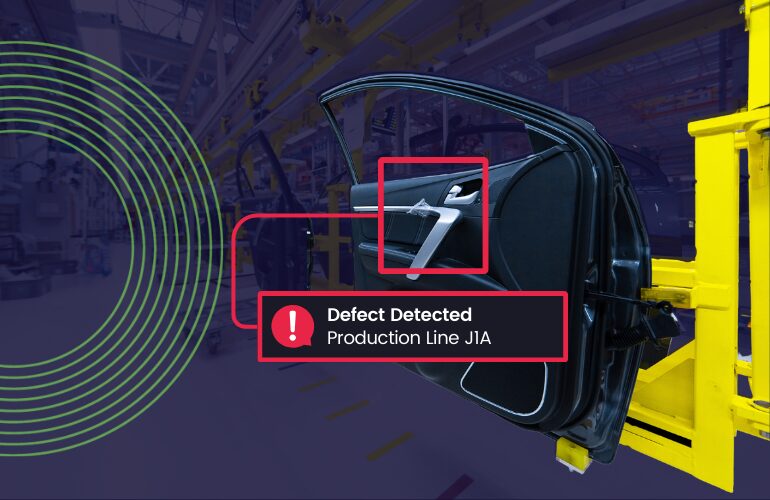

Computer vision (CV) is transforming quality control in manufacturing by using high-resolution cameras and sophisticated algorithms to automatically inspect products with precision. Techniques like edge detection, pattern recognition, and machine learning allow CV systems to spot defects, misalignments, and surface flaws with impressive accuracy.

These systems capture detailed images of products and analyze them instantly, making it possible to detect and fix issues in real-time. By integrating CV into quality control, manufacturers not only improve the accuracy of inspections but also speed up the process, ensuring that only products meeting strict quality standards move on to the next stage of production.

#2 Predictive Maintenance

Say goodbye to unexpected equipment failures and halted production lines! Computer vision is transforming predictive maintenance by enabling real-time monitoring of equipment with exceptional accuracy. Using high-resolution imaging and advanced data analysis, CV systems can detect early warning signs, such as cracks or unusual patterns, before they turn into costly breakdowns. This proactive approach allows manufacturers to address issues in advance, reducing unplanned downtime and ensuring smooth, uninterrupted production.

#3 Supply Chain Management

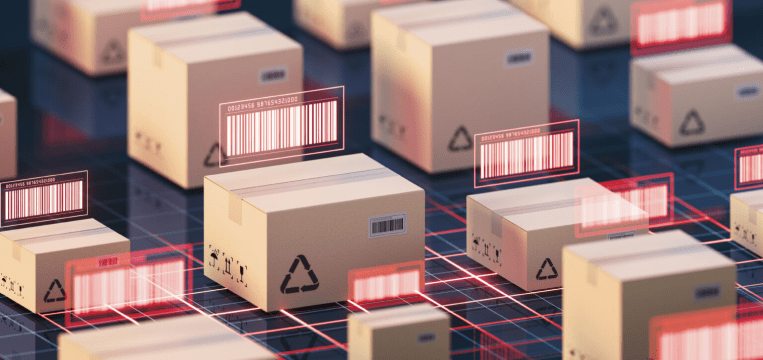

Revolutionize your supply chain with computer vision! This technology provides real-time tracking and enhanced accuracy, streamlining inventory management and logistics. Automated imaging systems and data analysis ensure efficient operations, reduce errors and offer instant insights for better decision-making.

Brainy Neurals has developed an advanced QR code scanner using OCR technology. This solution automates the tracking process, ensuring accurate inventory management and smoother logistics operations. With such innovations, your supply chain can achieve greater efficiency and agility.

#4 Safety

Ensuring safety in manufacturing is essential, and computer vision is revolutionizing workplace security. CV systems oversee production environments to enforce safety protocols, including monitoring compliance with personal protective equipment (PPE) requirements. By analyzing real-time video feeds, these systems ensure that workers are wearing the necessary protective gear, reducing accident risks and fostering a safer work environment.

Brainy Neurals has developed an innovative project using live camera feeds to verify if workers are wearing the required PPE. By simply providing access to the live feed, this advanced computer vision solution continuously monitors compliance, enabling real-time visibility into who is wearing PPE and ensuring adherence to safety standards on the shop floor.

#5 Robot Vision

Robot vision, powered by computer vision, is transforming manufacturing by enabling robots to see, interpret, and interact with their environment in sophisticated ways. This technology allows robots to perform complex tasks like precision assembly, meticulous inspections, and real-time adjustments with minimal human intervention. By incorporating computer vision, manufacturers can significantly boost efficiency, accuracy, and adaptability, making their production lines more agile and capable of meeting changing demands.

Benefits of Computer Vision in the Manufacturing Industry

#1 Precision-Driven Quality Control:

Computer vision systems excel at detecting tiny defects and inconsistencies that might be missed by the human eye. This precision ensures that every product adheres to strict quality standards, significantly reducing the likelihood of returns and boosting customer satisfaction.

#2 Accelerated Production Processes:

By automating visual inspections, computer vision dramatically accelerates manufacturing processes. This not only shortens production cycles but also enables manufacturers to meet tight deadlines and swiftly respond to market demands, thereby enhancing overall operational efficiency and productivity.

#3 Versatile Production Adaptability:

Computer vision technology equips robots with the ability to perform a wide range of tasks and adapt seamlessly to different products. This flexibility facilitates the rapid reconfiguration of production lines to accommodate new models or shifts in demand, making manufacturing processes more agile and responsive.

#4 Cost Efficiency and Waste Reduction:

Automating quality checks with computer vision reduces the need for manual inspections, leading to significant cost savings. By minimizing errors and operational waste, manufacturers can lower labor costs, improve resource utilization, and maintain competitive pricing while optimizing overall efficiency.

Challenges of Computer Vision in Manufacturing

#1 Lightening Conditions

- Variability: Fluctuating lighting conditions can significantly alter how objects appear in images, complicating the task of accurate recognition and analysis by computer vision systems.

- Shadows and Reflections: Shadows and reflections can obscure important details or create misleading signals, potentially leading to errors in object detection and recognition.

#2 Object Variability

- Variations: Objects may vary in size, orientation, and appearance due to manufacturing tolerances, wear and tear, or environmental factors. This variability makes it difficult for computer vision systems to generalize and accurately recognize objects.

- Occlusions: Objects can be partially hidden by other items, complicating the task of identifying and tracking them effectively.

#3 Data Quality and Quantity:

- Data Availability: Effective computer vision models require large, high-quality datasets for training and validation, but gathering such comprehensive, annotated data can be both time-consuming and costly.

- Data Annotation: Manually labeling data is a labor-intensive task prone to errors, which can negatively impact the accuracy and performance of the computer vision models.

#4 Computational Resources:

- Hardware Requirements: Sophisticated computer vision algorithms, especially those utilizing deep learning, demand significant computational power for both training and deployment.

- Cost: The specialized hardware and software needed to run these advanced algorithms can be expensive, posing financial challenges for some manufacturers.

#5 Integration and Deployment:

- Compatibility: Integrating computer vision systems into existing manufacturing operations often involves complex planning and customization to ensure seamless compatibility with current processes.

- Deployment Challenges: Implementing computer vision technology in harsh industrial environments—characterized by extreme temperatures, vibrations, and other stress factors—presents additional hurdles that must be addressed to ensure consistent and reliable performance.

Emerging Trends in Computer Vision and its impact on Manufacturing Industry

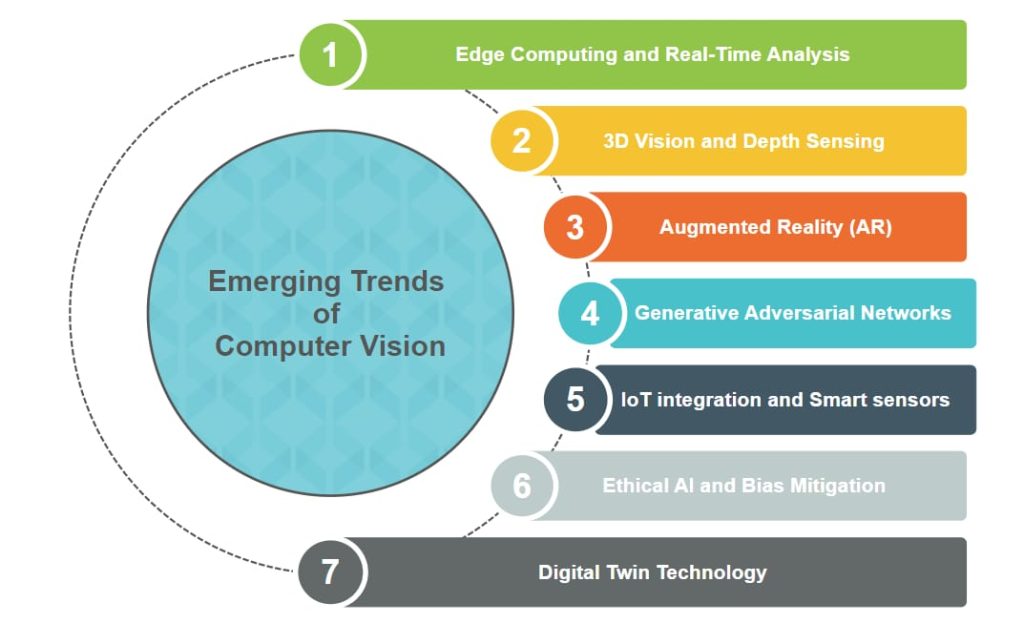

#1 Edge Computing and Real-Time Analysis

- Trend: With the rise of edge computing, computer vision systems are increasingly processing data locally on devices rather than relying solely on cloud-based processing. This reduces latency and improves real-time analysis.

- Impact: In manufacturing, this means faster detection of defects, real-time quality control, and immediate feedback on production processes.

#2 3D Vision and Depth Sensing

- Trend: The use of 3D vision and depth sensors is expanding, providing more detailed spatial information.

- Impact: This can be used for precise robotic manipulation, complex assembly tasks, and more accurate measurements of manufactured parts.

#3 Augmented Reality (AR) for Enhanced Human-Machine Interaction

- Trend: AR is being used to overlay computer vision data onto the physical world, enhancing human-machine interactions.

- Impact: In manufacturing, this can assist operators with real-time guidance, training, and visual overlays for maintenance tasks.

#4 Increased Use of Generative Adversarial Networks (GANs)

- Trend: GANs are being used to generate synthetic data and improve computer vision models.

- Impact: This can help in training models for rare defect types or uncommon scenarios, leading to better overall system performance.

#5 IoT Integration and Smart Sensors

- Trend: Integration of computer vision with IoT and smart sensors is growing.

- Impact: This enables more comprehensive monitoring of production lines, better data collection, and more effective system integration.

#6 Ethical AI and Bias Mitigation

- Trend: As computer vision systems become more prevalent, there’s an increasing focus on ethical AI and bias mitigation.

- Impact: Ensuring that computer vision systems operate fairly and transparently in manufacturing processes is crucial for maintaining quality and trust.

#7 Digital Twin Technology

A digital twin is a virtual replica of a physical system, continuously updated with real-time data to simulate and monitor processes.

- Trend: Creating digital twins of manufacturing systems that use computer vision data to simulate and monitor real-world processes.

- Impact: Digital twins can help in optimizing operations, predicting maintenance needs, and improving overall system performance by providing a virtual representation of the physical system.

Conclusion

In summary, computer vision is revolutionizing the manufacturing industry by offering advanced tools for quality control, predictive maintenance, and real-time analysis. As companies strive to meet increasing demands and enhance production, computer vision, especially from leading computer vision companies in India, emerges as a game-changing technology.

Recent advancements such as 3D vision, augmented reality, and generative adversarial networks (GANs) are further empowering computer vision. These innovations enhance quality inspections, enable more precise robotic operations, and seamlessly integrate with digital twins and edge computing. By providing in-depth insights and automating complex processes, computer vision helps manufacturers maintain higher product quality and streamline operations.

Looking ahead, as manufacturers continue to adopt and integrate these cutting-edge technologies, the future of manufacturing is set to become more efficient and adaptable. Computer vision is not only boosting productivity and quality but also promoting more sustainable practices. As this technology evolves, it will play a pivotal role in shaping a more agile and innovative manufacturing sector, poised to tackle the challenges and opportunities of a rapidly changing global market.

Where do you think computer vision will make the biggest impact next? Share your thoughts!