Discover how Brainy Neurals helped a government railway improve safety and reduce delays by using AI and computer vision to check and measure railway systems quickly and accurately during maintenance runs.

Industry: Public Transportation | Government Railways

Problem

Government railways struggled with safety risks and service disruptions due to manual inspections failing to identify micro-level faults in overhead systems. Issues such as pantograph wear, wire misalignment, and connection instability often remained undetected until critical failures occurred, leading to costly downtime.

Challenges

- Detecting small but critical defects (e.g. misalignments, wear, connection instability) across extensive routes at high speed

- Ensuring high accuracy with minimal false positives

- Maintaining reliable performance regardless of lighting or weather conditions

- Selecting cameras capable of capturing high-clarity depth and visual data at operational speeds

- Ensuring detection reliability across diverse lighting and weather conditions

Solution

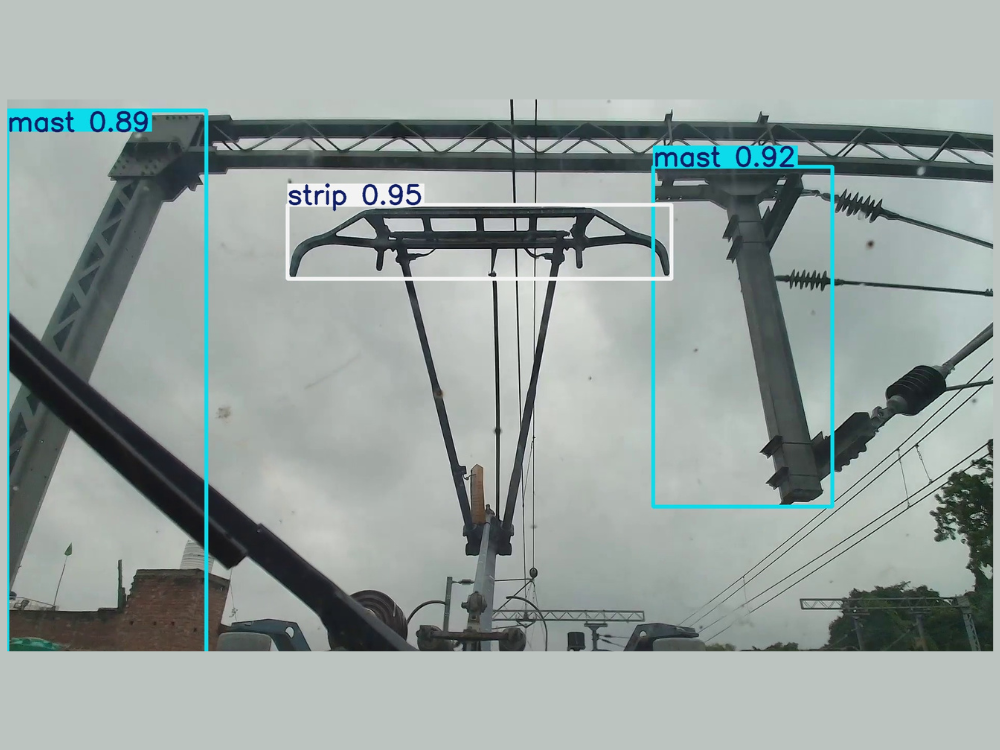

Brainy Neurals deployed an advanced Edge AI-powered computer vision system on railway wagons. Using high-frame-rate cameras and depth sensors, the solution intelligently detected and measured critical parameters of railway infrastructure components – including pantographs, masts and other assemblies – during high-speed operations.

The AI models processed data in real time to identify wear, misalignments, or deviations from safety standards, and generated precision GPS-tagged alerts. Maintenance teams accessed these insights via a robust desktop-based interface, enabling proactive decision-making and targeted intervention planning.

Technologies

Edge AI | Computer Vision | High FPS Cameras | Depth Sensors | GPS Integration

Results

- Transformed inspections from manual to intelligent, measurement-driven operations

- Enabled predictive maintenance, reducing unplanned downtime

- Improved emergency response with accurate, GPS-based location tagging

- Increased team productivity through a significant reduction in false alarms

- Achieved an 87% reduction in unexpected failures and a 62% drop in service delays