If you search for AI in tire manufacturing, most content talks about automation or visual inspection.

But inside a real plant, the problem is different.

Uniformity rejection increases.

Scrap remains above 2–3%.

OEE struggles to cross 70–75%.

Inspection systems detect defects correctly.

SPC charts show no violations.

Yet yields have not improved.

Most tire manufacturers do not have a detection problem. They have a process of interaction and traceability problem across the tire production line.

True AI-powered defect detection in tire manufacturing creates value only when inspection signals are connected to upstream variability across:

- Rubber mixing

- Tread and sidewall extrusion

- Green tire building

- Tire curing process

- Uniformity testing and X-ray inspection

Without this linkage, AI improves visibility. It does not reduce scraps. This is where AI-based quality control in tire manufacturing becomes critical.

Why Traditional Quality Systems Fail in Tire Manufacturing

A single rejected tire may depend on:

- Banbury torque variation

- Mooney viscosity drift

- Extrusion die pressure instability

- Belt centering deviation

- Press cavity temperature imbalance

- Operator variability

These signals live across PLCs, historians, MES, and inspection systems.

The real challenge is cross-stage causality modeling in tire production processes. This is exactly where AI for scrap reduction in tire plants delivers a measurable impact.

1. AI in Rubber Mixing: Predicting Compound Variability

The Production Challenge

Rubber mixing in tire manufacturing directly affects durability, rolling resistance, and uniformity.

Common variability drivers:

- Rotor load fluctuations

- Moisture variation

- Mixing cycle inconsistency

- Internal mixer temperature gradients

- Manual adjustments

Traditional systems monitor thresholds. They don’t interpret multi-variable patterns. A batch can be “within tolerance” and still create downstream defects.

AI-Based Solution

Technology used:

- Time-series machine learning

- Anomaly detection in manufacturing

Key capabilities:

- Capture torque curves and mixer power data

- Train supervised models using defect-tagged batches

- Predict downstream defect probability

- Integrate AI insights into MES dashboards

This is AI-driven quality optimization in tire manufacturing, not just monitoring.

Business Impact

- Reduced mixing-related scrap

- Improved compound consistency

- Higher first-pass yield in tire production

- Lower uniformity rejection

Mixing becomes predictive instead of reactive.

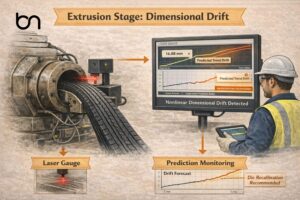

2. AI in Tire Extrusion: Preventing Dimensional Drift

The Production Challenge

Tire extrusion process control requires dimensional precision.

Over time, die wear and viscosity shifts introduce drift:

- Thickness variation

- Pressure oscillation

- Tool degradation

- Flow instability

Most plants detect deviation only after limits are exceeded.

AI-Based Solution

- Real-time laser gauge integration

- Drift forecasting using regression models

- Nonlinear trend detection

- Edge AI deployment for real-time alerts

This is an industrial AI for extrusion stability.

Business Impact

- Reduced material overuse

- Lower rework rates

- Extended die lifespan

- Improved tread consistency

Detection shifts from limit-based to trend-based.

3. AI-Powered Defect Detection in Green Tire Building

The Production Challenge

Green tire building process defects include:

- Belt centering errors

- Ply overlap variation

- Concentricity deviation

- Tension imbalance

Most are discovered during final inspection.

AI-Based Solution

Technology used:

- Computer vision in tire manufacturing

- Deep learning for defect detection

- Sensor fusion

Key capabilities:

- High-resolution camera deployment

- CNN-based defect detection

- Real-time alignment monitoring

- Edge inference for correction

This enables real-time AI-powered defect detection in tire assembly lines.

Business Impact

- Reduced structural rejection

- Improved radial and lateral uniformity

- Lower warranty risk

- Increased first-pass yield

Quality moves upstream.

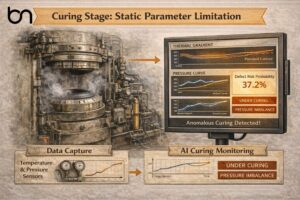

4. AI in Tire Curing Process: Adaptive Optimization

The Production Challenge

The tire curing process traditionally runs on fixed temperature and pressure recipes.

But compound variability changes curing response.

Common issues:

- Under-curing

- Over-curing

- Uneven hardness distribution

- Pressure imbalance

Static recipes cannot adapt dynamically.

AI-Based Solution

Technology used:

- Deep learning time-series models

- LSTM / Transformer-based modeling

Key capabilities:

- Pressure and temperature curve modeling

- Defect probability prediction

- Dynamic parameter adjustment

- Correlation with upstream mixing data

This enables AI-driven adaptive curing in tire manufacturing.

Business Impact

- Reduced curing-related defects

- Lower energy consumption per tire

- Improved durability consistency

- Stabilized OEE

Curing becomes intelligent.

5. AI-Integrated Final Inspection in Tire Manufacturing

The Production Challenge

Tire inspection systems (X-ray and uniformity testing) operate in silos.

Limitations include:

- Disconnected datasets

- Recurring defect categories

- Delayed root cause analysis

Inspection identifies failure.

It does not prevent recurrence.

AI-Based Solution

Technology used:

- Multi-stage correlation modeling

- AI analytics for manufacturing

Key capabilities:

- Cross-stage data aggregation

- Defect-driver identification

- Structured AI-generated root cause summaries

- Predictive quality dashboards

This creates closed-loop AI-based quality optimization in tire plants.

Business Impact

- Faster root cause identification

- Reduced repetitive defect cycles

- Improved cross-functional visibility

- Data-driven quality governance

6. Predictive Maintenance in Tire Manufacturing Using AI

The Production Challenge

Equipment instability affects quality and OEE:

- Bearing wear

- Hydraulic drift

- Motor overheating

Time-based maintenance is inefficient.

AI-Based Solution

Technology used:

- Predictive maintenance in tire manufacturing

- Vibration analysis using machine learning

Key capabilities:

- Vibration spectrum monitoring

- Thermal anomaly detection

- Failure probability estimation

- Condition-based maintenance alerts

Business Impact

- Reduced unplanned downtime

- Stabilized OEE

- Lower repair costs

- Reduced defect spikes

Stable machines enable stable quality.

What AI Really Changes in Tire Manufacturing

AI in tire production does not replace engineers.

It enhances them with:

- Large-scale pattern recognition

- Cross-process intelligence

- Predictive defect prevention

- Real-time quality optimization

When implemented correctly, AI-powered quality optimization in tire plants delivers:

- Scrap reduction

- Higher first-pass yield

- Energy optimization

- Faster defect containment

- Reduced warranty risk

- Improved operational stability

This is not automation for the sake of automation.

It is predictive quality control embedded into tire manufacturing systems.

Conclusion

The tire manufacturing industry is entering a phase where reactive inspection and threshold-based monitoring are no longer sufficient. Variability across mixing, extrusion, building, curing, and equipment health demands connected intelligence. This is where AI in Tire Manufacturing creates real value by linking process behavior to quality outcomes and enabling true AI-powered defect detection in tire manufacturing rather than isolated reporting.

When deployed strategically, AI-based quality control and predictive maintenance in tire plants reduce scrap, stabilize OEE, and improve first-pass yield by identifying patterns that traditional systems cannot interpret. From computer vision on assembly lines to time-series modeling for curing and mixing optimization, AI shifts production from reactive correction to predictive control.

At Brainy Neurals, an Ai development company in India, we focus on delivering production-ready AI solutions for tire manufacturing that integrate directly with plant systems and drive measurable scrap reduction in tire manufacturing. The objective is simple: transform plant data into actionable intelligence and convert operational complexity into sustained competitive advantage.