Pharmaceutical manufacturing runs on trust, a trust that every batch was produced exactly as intended, under controlled conditions, and with patient safety as the top priority. Regulators don’t rely on assumptions or intent; they rely on proof.

That proof comes from GMP (Good Manufacturing Practice) documentation.

In pharmaceutical manufacturing, GMP documentation is not administrative paperwork, it is the legal and scientific evidence that quality requirements were met. It records what was done, when it was done, how it was done, and under which controls across activities such as line clearance, material loading, in-process checks, packaging, deviations, and CAPA.

Manufacturing equipment may produce tablets, capsules, or injectables, but documentation determines whether those products are legally allowed to enter the market. In regulatory terms, if it isn’t documented, it didn’t happen.

Despite decades of GMP enforcement and digital systems like MES, QMS, and eDMS, documentation-related failures remain among the most frequent regulatory observations, not because records are missing, but because they often fail to convincingly prove that recorded events reflect what physically occurred on the shop floor.

As pharmaceutical operations become faster and more complex, this gap between execution and evidence is where AI in pharmaceutical quality compliance and broader AI in pharma documentation become essential.

How GMP Documentation Works Today and Where It Falls Short

Most GMP documentation is designed around process intent and depends on human confirmation to prove that intent was fulfilled. Operators tick checkboxes, supervisors verify entries later, and QA reviews records hours or days after execution.

This introduces predictable weaknesses:

- Delayed or retrospective entries

- Transcription and interpretation errors

- Missing physical and visual context

- Undocumented corrections

- Heavy dependence on memory and assumptions

Even in facilities running advanced MES and electronic batch records, many critical GMP activities still rely on manual visual confirmation such as line clearance, material loading, configuration checks, and visual inspections.

Regulators increasingly focus on this disconnect between documented intent and executed reality. Data integrity findings typically arise not because documentation is absent, but because documentation cannot convincingly demonstrate what actually happened.

From Manual Checks to Evidence-Based Documentation

Documentation fails where evidence is inferred.

Documentation succeeds where evidence is directly observed.

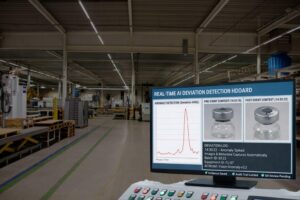

This is where AI in pharmaceutical manufacturing, particularly computer vision and edge AI, changes the foundation of GMP documentation.

Computer vision enables systems to interpret images and video in a structured, measurable way of detecting presence, absence, orientation, cleanliness, and change over time.

Edge AI means this analysis happens locally, near the equipment or camera, rather than in a remote cloud ensuring real-time response, deterministic behavior, and data integrity, all of which are critical in GMP environments.

Instead of relying on operators to confirm what they observed, AI systems observe the shop floor directly, capture time-stamped visual evidence, and convert it into structured, traceable GMP records.

AI does not replace quality systems. It becomes the evidence-generation layer that strengthens them.

Why AI Is Becoming Practical for GMP Compliance

AI adoption in pharmaceutical quality operations is accelerating, not as experimentation, but as infrastructure.

- The automated machine vision inspection market for pharmaceutical quality control was valued at approximately USD 1.18 billion in 2025 and is projected to reach USD 2.81 billion by 2034, driven by compliance pressure and rising operational complexity. This growth reflects the broader maturity of AI in pharma beyond research and analytics.

- Regulatory bodies including the FDA and EMA increasingly acknowledge AI’s role in quality systems, provided it is transparent, validated, and governed under formal change control.

How AI Can Be Used Across GMP Activities

-

Line Clearance Documentation

- The Problem

Line clearance relies on manual visual inspection followed by checklist sign-off. Documentation typically states “line cleared” without objective proof, making it one of the most common sources of FDA 483 observations. - AI Solution

Industrial cameras are installed at predefined clearance zones such as conveyors, feeders, hoppers, and reject bins. At clearance trigger points, images are captured automatically. Using computer vision segmentation models, the system verifies the absence of foreign materials by comparing the live scene against a validated clean reference state. Anomaly detection models flag unexpected objects or configurations without requiring predefined defect classes. Inference runs on edge AI devices, ensuring deterministic execution.

- Documentation Impact

Each clearance event generates immutable evidence of images, timestamps, model outputs, equipment ID, batch ID, and SOP references directly linked to GMP records.

- Material Loading and Component Verification

- The Problem

Incorrect material loading is a high-impact deviation, often investigated without objective proof. - AI Solution

Object detection and classification models verify component type, SKU, and count. Vision-based OCR and barcode recognition validate labels and lot numbers. Pose estimation models confirm correct orientation where required. The system can block progression automatically if mismatches are detected. - Documentation Impact

Machine-generated loading evidence replaces handwritten confirmation in batch records, strengthening AI in pharma documentation workflows.

-

In-Process Inspection Documentation

- The Problem

In-process checks are frequently documented as numeric values or “OK” entries without raw evidence. - AI Solution

Segmentation and keypoint detection models quantify physical states such as fill level, alignment, cleanliness, and configuration against approved tolerances. Each inspection produces images, inference results, confidence metrics, and timestamps. - Documentation Impact

In-process checks become evidence-based measurements instead of symbolic confirmations.

-

Packaging Documentation (Blister, Label, Carton)

- The Problem

Packaging documentation often records summary counts while losing defect context. - AI Solution

High-speed computer vision pipelines inspect blister cavities, orientation, label presence, and print quality at line speed. Anomaly detection identifies previously unseen defect patterns. - Documentation Impact

Each reject is linked to stored visual evidence tied to the batch and inspection step.

-

Deviation Detection and Investigation

- The Problem

Deviations are often detected late and investigated based on assumptions rather than data. - AI Solution

Continuous visual anomaly detection monitors operational patterns. When deviations occur, pre-event and post-event visual context is automatically captured. - Documentation Impact

Deviation reports reference objective visual evidence instead of narrative reconstruction.

-

CAPA Effectiveness Documentation

- The Problem

CAPA effectiveness is often documented qualitatively, making prevention claims difficult to defend. - AI Solution

Vision analytics track defect rates, anomaly scores, and stability metrics before and after CAPA implementation. - Documentation Impact

CAPA closure includes quantitative, trend-based evidence of effectiveness.

SOP Compliance Verification

- The Problem

SOPs describe intent, but execution is assumed. - AI Solution

Rule-based vision checkpoints verify SOP-defined visual actions such as cleanliness, setup, and configuration in real time. - Documentation Impact

SOP compliance becomes provable rather than inferred.

How Generative AI Supports GMP Documentation

While computer vision and edge AI focus on observing physical reality, Generative AI (GenAI) supports the documentation and analysis layer within AI in pharmaceutical quality systems.

GenAI can:

- Summarize deviation timelines using captured evidence

- Assist in drafting investigation narratives grounded in objective data

- Support CAPA rationale using trend-based insights

- Improve consistency and clarity of quality documentation

Importantly, GenAI does not generate evidence; it contextualizes validated evidence produced by vision systems.

Validation, Change Control, and Regulatory Alignment

AI systems used in GMP environments are validated as computerized systems. Validation defines intended use, model boundaries, performance thresholds, failure modes, and worst-case scenarios.

Inference pipelines are deterministic. Model updates follow formal change control with impact assessment and regression testing aligning AI behavior with CSV expectations, not bypassing them.

Integration with GMP Documentation Systems

AI-generated evidence integrates with MES, eDMS, QMS, and electronic batch records. Images, inference outputs, and metadata are stored as official GMP records with audit trails and access control.

Batch records reference evidence IDs. Deviations reference captured events. Auditors access original data without reconstruction.

Why This Reduces Cost Instead of Adding It

The largest documentation costs in pharma arise from batch rejection, investigation labor, CAPA cycles, audit remediation, and regulatory delays.

By replacing subjective confirmation with machine-generated, evidence-based documentation, AI in pharma reduces these costs through faster investigations, fewer findings, and higher audit confidence.

Conclusion

GMP documentation challenges persist because evidence generation remains manual, indirect, and assumption driven.

- Computer vision observes reality.

- Edge AI secures it.

- Generative AI contextualizes it.

Together, they transform GMP documentation from a retrospective record into a real-time, evidence-driven quality system strengthening compliance, reducing risk, and enabling scalable pharmaceutical operations.

For pharmaceutical organizations exploring AI in pharmaceutical quality compliance, working with an experienced AI development company in India can accelerate implementation while ensuring regulatory alignment, validation readiness, and cost-effective deployment.