Remember the Tylenol tragedy of 1982? Seven people died because someone tampered with medicine bottles. That single incident changed everything about how we package pharmaceuticals. Within months, the FDA mandated tamper-resistant packaging for all over-the-counter drugs.

Fast forward to today – your facility probably has foil seals, breakaway caps, shrink bands, and multiple layers of protection. You’re checking thousands of units every shift. Your QC team is doing their best, but here’s the uncomfortable truth: human inspection has limits.

Can your team catch a 2mm gap in an induction seal at line speed? Can they spot a cleverly re-applied shrink band? Can they maintain the same level of attention on the 10,000th bottle as they did on the first?

This is where AI in pharmaceutical manufacturing steps in – not to replace your team, but to give them superpowers.

The Real-World Problem You’re Facing

An audit is coming up, and you’re reviewing your tamper-evident packaging records. You spot-check samples, maybe 5-10% of production. But what about the other 90-95%?

Here’s what keeps pharma QA managers up at night:

- Partial seal failures that look fine to the naked eye but could allow contamination

- Reapplied tamper bands that someone spent time making look “almost perfect.”

- Batch-to-batch inconsistencies in capsule banding that slip through

- False positives from breakaway rings that break during transport, not tampering

And the stakes? A single missed defect could mean:

- Product recalls costing millions

- FDA warning letters

- Damaged brand reputation

- Worst of all – patient safety at risk

How AI Actually Works on Your Production Line

Let’s get practical. You don’t need a PhD in machine learning to understand this. Think of AI vision systems as incredibly attentive inspectors that never blink, never get tired, and learn from millions of examples.

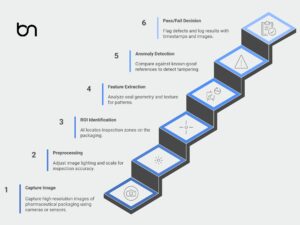

AI (Computer Vision) Process for Tamper Detection

Here’s how AI actually inspects each package, seal, or capsule on your line — in real time:

- Capture Image or Sensor Data

Cameras (RGB, thermal, or hyperspectral) or sensor arrays capture visual or physical data from every unit. - Preprocessing & Normalization

Images are adjusted for lighting, alignment, angle, and clarity — ensuring every input is standardized before analysis. - Region of Interest (ROI) Identification

AI automatically identifies and focuses on specific inspection zones like seal centers, capsule bands, label corners, or shrink seams. - Feature Extraction & Pattern Analysis

Algorithms analyze visual patterns (e.g. heat maps, textures, edges, seal geometry, torque curves) and compare them to baseline “good” data. - Anomaly Detection

Any variation — even slight — that doesn’t match trained expectations is flagged as a potential tamper attempt or defect. - Pass/Fail Decision & Logging

If an issue is found, the unit is rejected instantly. The result is logged with timestamp, image, defect classification, and traceability details for GMP records.

It’s a digital inspector — trained, validated, and fully auditable.

1. Induction Foil Seals: Seeing the Invisible

Your capping machine seals bottles at high speed. But how do you know every seal is perfect without opening each one?

The AI Solution:

Thermal imaging cameras “look through” the cap immediately after sealing. The foil is still warm from the electromagnetic heating process. A good seal has a specific heat pattern – circular, symmetric, consistent temperature.

The AI model has seen thousands of perfect seals and thousands of bad ones. It instantly recognizes:

- Cold spots = under-sealed areas where the foil didn’t bond

- Hot spots = overheating that could char or deform the seal

- Asymmetric patterns = torque issues or edge lifts

The best part? This happens in real-time, bottle by bottle, without slowing down your line. No caps removed, no destructive testing, just instant validation that meets GMP requirements.

Instead of sampling 100 bottles per batch, you’re inspecting 100,000. Every. Single. One.

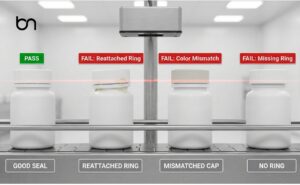

2. Breakaway Cap Rings

You’ve probably seen this: a broken ring that makes you wonder – “Did this break during shipping or was it tampered with?”

Sophisticated tampering is rare but real. Someone could:

- Swap a cap with a new one from another bottle

- Re-attach a broken ring with adhesive

- Heat-weld it back on

The AI Solution:

High-resolution side cameras scan each bottle as it leaves the capping station. The deep learning model checks:

- Is the ring present and positioned correctly?

- Are the fracture lines clean and uniform (not melted or reattached)?

- Do the cap and ring colors match exactly?

But here’s where it gets clever: AI also reads your torque sensor data. Every cap application creates a unique “torque signature” – how much force it took to tighten, and the pattern of resistance.

A reused cap has a different signature. It’s already been threaded once, so the second engagement feels different. The AI learns these subtle differences.

You catch not just missing rings, but sophisticated tampering attempts that would fool visual inspection.

3. Shrink Bands

Walk through your packaging line right now. Look at those shrink sleeves on bottle necks. They probably look fine, right?

But what if someone carefully removed one, tampered with the contents, and applied a new sleeve? With the right equipment, they could shrink it back on. The question is: can you tell the difference?

The AI Solution:

AI cameras scan for:

- Perfect symmetry – original sleeves have machine-precision alignment

- Even shrink tension – counterfeit bands often show bubbles or irregular folds

- Texture consistency – the surface reflectivity changes slightly with reheating

- Micro-tears or fused edges – telltale signs of reapplication

The system compares each sleeve to thousands of known-good examples. It spots deviations in milliseconds.

Your last line of defense (the tamper sleeve) is now verified on every single unit, not just samples.

4. Capsule Banding

You use banded capsules because they’re tamper-evident. But banding quality varies – air bubbles, uneven width, color inconsistencies.

Someone could scrape off a band, swap capsule contents, and reapply gelatin with food coloring. It might look okay to the human eye, especially if your inspector is checking hundreds per hour.

The AI Solution:

High-speed cameras with 360-degree scanning check every capsule for:

- Bandwidth and thickness uniformity

- Edge line sharpness

- Color consistency (no specks or bleeds)

- Surface anomalies like air bubbles

Because the system rotates the capsule digitally, even partially visible bands get fully inspected.

FDA-compliant tamper evidence on every oral solid dosage unit, with documentation to prove it.

5. Blister Packs

A clever counterfeiter can heat-open a blister cavity, swap tablets, and reseal with adhesive. The defect might be a tiny foil lift at one corner – easy to miss in visual inspection.

The AI Solution:

Post-sealing inspection cameras analyze:

- Seal line geometry across all cavities

- Foil reflectivity patterns

- Depth and contour of each pocket

- Any pinholes, lifts, or color variations

The AI is especially good at catching “almost defects” – subtle anomalies that don’t fit the pattern of known-good packs.

Every cavity in every blister card is verified, meeting the GMP expectation of batch-wide integrity.

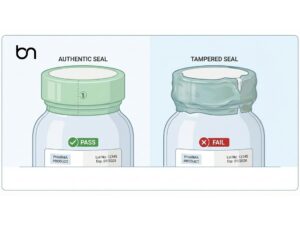

6. Tamper Labels and VOID Seals

Those VOID stickers on cartons? They can be peeled slowly and reapplied, especially in humid conditions. Some counterfeiters even print replica labels.

The AI Solution:

OCR and surface inspection systems check:

- Is the VOID pattern intact and aligned correctly?

- Are there residue marks or fiber tears?

- Does the holographic effect match the original?

- Is the label tilted, skewed, or showing gloss variations?

Combined with serialization data, AI ensures each seal matches the correct product batch and hasn’t been reused.

Your final packaging barrier is verified before shipping, reducing recall risk.

The Compliance Angle You Can’t Ignore

Let’s talk about what auditors actually want to see. It’s not just about catching defects – it’s about proving you caught them.

Automated GMP Documentation

Modern AI in pharma manufacturing systems create audit trails automatically.

- Product serial number

- Inspection result (pass/fail/specific defect)

- Equipment ID (which AI system did the check)

- Exact timestamp

- Operator credentials (who was supervising)

This meets FDA 21 CFR Part 11 and EU Annex 11 requirements for electronic records. The records are:

- Timestamped – you know exactly when each check happened

- Immutable – can’t be altered after creation

- Traceable – linked to specific batches and lot numbers

- Secure – access-controlled and backed up

For your next audit: Instead of showing sample inspection logs, you can pull up complete inspection data for every unit in a batch. Instant recall of any production record, with full traceability from raw materials to distribution.

AI Model Validation

Regulators are asking the right question: “How do you know your AI actually works?”

This is where model cards come in. Think of them as a technical passport for your AI system, documenting:

- What the model was designed to detect

- What training data was used (and its limitations)

- Performance metrics (accuracy, false positive rates)

- Known biases or failure modes

- Validation protocols performed

Following GAMP5 guidance, you perform risk assessments and validation just like any other critical GxP system. The AI isn’t a black box – it’s a qualified piece of equipment with documentation to prove it.

Beyond Tamper Detection: The Full Picture

Once you have AI vision systems on your line, you can tackle other compliance headaches:

Label Verification: Remember that 2024 statistic? Nearly half of US pharma recalls were due to labeling errors – wrong ingredients listed, missing warnings, incorrect lot numbers.

AI-powered OCR reads every label and compares it to specifications:

- Ingredient lists

- Warning statements

- Lot and expiration dates

- Barcodes and Datamatrix codes (verified to ISO standards)

A mismatch? The system flags it immediately, before that unit ships.

Inspector Consistency: Your day-shift QC inspector and night-shift inspector might have different interpretations of what counts as a “minor defect.” After 8 hours, even the best inspector’s attention drifts.

AI applies identical criteria to every unit, 24/7. No fatigue, no subjectivity, no “it was close enough.” If you train the model that a 3mm seal gap is a reject, it will catch every 3mm gap, on every shift, forever.

Serialization Integrity: DSCSA in the US and FMD in the EU require every package to have a unique, traceable identifier. AI vision equipment reads each code and cross-checks it instantly:

- Is the code readable?

- Has it already been used (duplicate)?

- Does it match the batch being packaged?

Conclusion

Tamper-evident packaging has been protecting patients since 1982. But the threats have evolved. Counterfeiters are more sophisticated. Regulatory expectations are higher. Production volumes keep growing.

Your human inspectors are doing their best, but they can’t inspect 100% of production with consistent accuracy. They can’t see through caps with thermal imaging. They can’t cross-reference serialization databases in real-time.

AI in pharma manufacturing can.

The question isn’t whether AI will become standard in pharma manufacturing intelligence – it’s already happening at leading manufacturers.

Because every day without automated inspection is another day of:

- Sampling-based uncertainty

- Potential audit findings

- Risk of recalls

- Manual documentation burden

And every day with it is:

- 100% inspection coverage

- Real-time defect detection

- Automated GMP records

- Peace of mind

At Brainy Neurals an AI development company in India, we’ve been building AI data solutions for pharmaceutical companies for over 8 years. Our team includes expert AI engineers and experienced pharma QA consultants who help us align every system with real pharma quality standards with vision AI.

If you’re looking for a team that understands regulated industries inside and out – let’s talk.

The 1982 Tylenol tragedy taught us that packaging matters. Today’s AI technology ensures we never forget that lesson.