Digital Twin Simulation for Container Operations

We developed a Digital Twin simulation system to replicate and analyze container operations in a real-world shipping environment. By modeling vessel, crane, and container workflows through discrete-event simulation, it helps logistics teams visualize performance, identify bottlenecks, and optimize operations before implementation.

Optimized Segmentation Model for Garbage Detection

We built an optimized segmentation system to detect and classify different types of waste in real time. By enhancing model speed and accuracy through hybrid CPU-GPU inference, the solution enables faster sorting, smarter recycling, and sustainable automation across waste-management facilities.

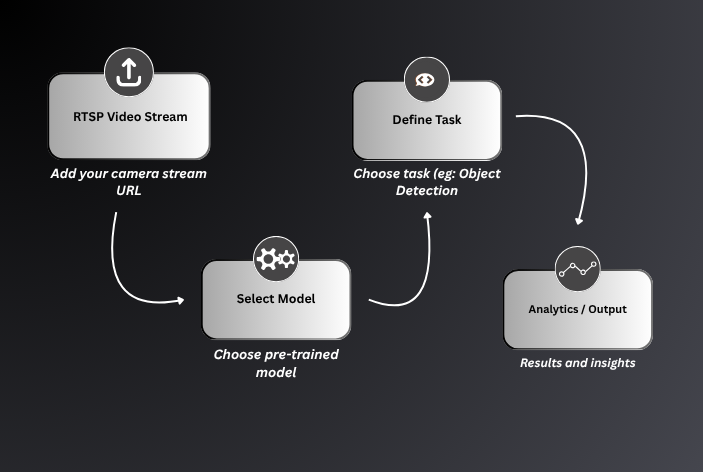

No-Code Computer Vision Platform

We built a no-code computer vision platform that enables users to create, train, and deploy custom AI models without writing a single line of code. The system simplifies the entire computer vision workflow from data upload and model selection to training, testing, and deployment all through a user-friendly interface designed for non-technical teams.

Smart Greenhouse Monitoring and Automation System

We developed a computer vision and AI-based greenhouse monitoring system that tracks plant health, environmental conditions, and resource usage in real time. The solution integrates sensor data, image analysis, and automation workflows to optimize temperature, humidity, and irrigation , ensuring better yield and resource efficiency in controlled agricultural environments.

Basketball Video Analytics and Player Tracking System

AI-Based Safety Monitoring System

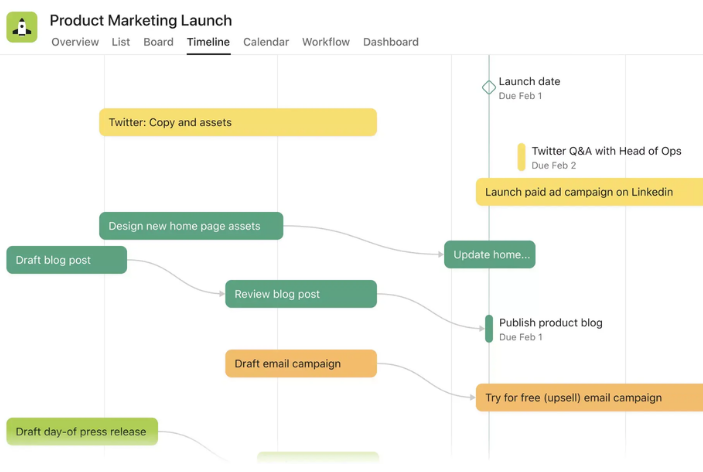

Automated Product Research and Scoping Workflow System

We developed an automation system that transforms manual product research and scoping into a seamless, data-driven workflow. By integrating Asana, SEMrush, and Google Workspace APIs, the system automatically collects market data, creates analysis sheets, and updates project statuses saving hours of manual effort for product research teams.